Media Library / Images

In order to send you the picture material you need, please click some examples – after receipt of your E-Mail we will personally contact you to hear your exact requirements.

Category

- All

- Products

- Applications

- Company

Applications

- All

- Petrol Station Equipment

- AdBlue® Refilling

- Tank Truck Equipment

- Alternative Fuels

- Chemicals

- LPG / DME

- Pharmaceuticals

- CNG / NGV

- Aircraft Refuelling Equipment

- LNG

- Rail Tankers

- H2 Hydrogen

- Ships & Marina

- LH2 Hydrogen

- Rubber Expansion Joints

- Hose Reels

Sales Division

- All

- SAT(Hoses and Fittings)

- EHT(Petrol Pump Nozzles and Accessories / Hoses)

- ERV(Rubber Expansion Joints)

Sorting

- Newest on top

- Alphabetical

Filter by keyword

1729 images found

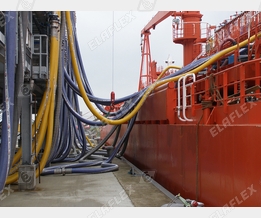

ERV-BR 100.16

BR Rubber Expansion Joint, special type for abrasive media such as sludges, slurries, solid / liquid mixtures and emulsions, dustlike or powdery products. Also suitable for all kinds of water (non oil containing) as well as various chemicals. Not suitable for petroleum based products. For extreme strain (e. g. sharp and rough-edged matter) we suggest the use of ERV with inner protection sleeve type SR.