Media Library / Images

In order to send you the picture material you need, please click some examples – after receipt of your E-Mail we will personally contact you to hear your exact requirements.

Category

- All

- Products

- Applications

- Company

Applications

- All

- Petrol Station Equipment

- AdBlue® Refilling

- Tank Truck Equipment

- Alternative Fuels

- Chemicals

- LPG / DME

- Pharmaceuticals

- CNG / NGV

- Aircraft Refuelling Equipment

- LNG

- Rail Tankers

- H2 Hydrogen

- Ships & Marina

- LH2 Hydrogen

- Rubber Expansion Joints

- Hose Reels

Sales Division

- All

- SAT(Hoses and Fittings)

- EHT(Petrol Pump Nozzles and Accessories / Hoses)

- ERV(Rubber Expansion Joints)

Sorting

- Newest on top

- Alphabetical

Filter by keyword

1729 images found

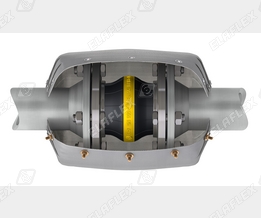

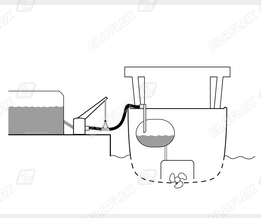

ERV TA:

ERV with white PTFE lining. Used when the chemical resistance of the chosen ERV type is insufficient. Resistant to all commonly used liquids. Electrically isolating, therefore not suitable for flammable liquids in Ex-Zones. Admissible working temperature of expansion joint has to be observed. For maximum pressure of 6 bar – not suitable for vacuum.